Personal Reflection

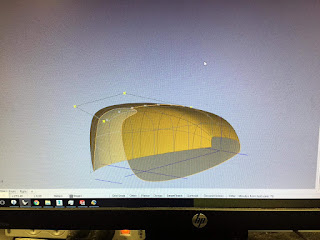

Fuel Tank

The project I’ve chosen to do the reflection is the fuel tank because this project costed me the longest time to complete it among other projects. In the process of making the fuel tank, I failed three times because of the accidental edge crack. First of all, lets discuss the weaknesses of this project. In the process of shaping the aluminium sheet, we need to change its radian from two different directions (horizontal, vertical). And it is very easy to break in the edge because of the hard hammering. The tear would be bigger and bigger if we didn’t give up the work. As we mentioned above, we need to change its radian in two directions. The aluminium sheet is soft and easy to be shaped comparing with other metals so it is also easy to deform. For example, when the horizontal radian fits the model shape, then we try to change the vertical radian. The whole aluminium plate will change the shape because of hitting force. This problem is such a big test of our patience. Secondly, because the adjustment of radian, I hit the aluminium plate too many times, which cause that the whole plate bends outward. When I compared my aluminium plate against the fuel tank model, I found that the upper part of the sheet was far away from model. Also, under this situation, the aluminium is already bend so it’s very hard to recover it. The last thing is that the aluminium plate breaks easily. We have to give up the broken one otherwise the crack would destroy the whole work. If the crack is very fine and small, we can use chopper to cut it out.

Because I failed many times during the making process. I tried to use different machines to make my project. In the send attempt, I chose a big machine outside the design lab. It has three long iron roller and its manual control. It can help us to change the radian of metal plate. I used to see one classmate completed his project by only using this machine and there has no scratch or any hammering marks on the plate. In shorts, his project looks very smoothly and wonderful. Unfortunately, this machine requires high skill and proficiency so I was not able to use that machine to complete my work. In addition, we can also use English wheel to change its radian until it close to the model. And English wheel shape the aluminium but remain the smooth surface. It is a better choice than only hammering the aluminium plate. There is a machine outside the design lab, which is opposite to the rollers. (sorry about that I can’t remember its name) it looks similar to a chopper but every time we press it against our aluminium plate, it can make the marks and bend the edge for a little bit. It’s good to change the radian for our work as well.

Second try: this time I use the rollers to change the aluminium plate roughly and use the English wheel and hammer to shape it alternatively. According to the failure from the past, I think this method is the best method to make a perfect radian.

The tools I used:

· The rollers

· Chopper

· File

· Hammers

· Tin snips

· Guillotine

· Sand bag

· English wheel

Using the machine with three rollers outside the design lab and give it a rough curve. So it will be easy to shape.

After using the rollers, it was bended for a little bit. I used hammer against this holder to bend it in order to fit the model properly.

Kept hammering it against the sand bag and using English wheel to smooth its surface. I don't want my project has too many dents on it, so English wheel is a good way to recover those dents by hammering.

Comparing with other’s project

I got the same problem as before I experienced, the edge got curved when I hit on the middle part. I browsed some classmate's works, the excellent works' surface looks very smooth and it fits the model perfectly. My work can't fit the model perfectly because I couldn't hit the aluminium plate evenly, which cause the dent and shrink.

Reflection on my discipline

This course gave me a deep understanding of the metal as a type of construction materials. Also, it provides a chance to me to be familiar with many digital making tools, equipments and software. Before, we only learn the knowledge about construction through the books and lecture. However, this course gave us a opportunity to create and understand what is digital making. Also, I've learn how to shape the metal and make a craft work. This course also encourage me to learn more about craft skill and metal materials in the future.

Comments

Post a Comment